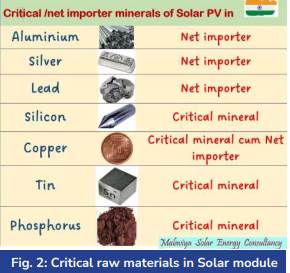

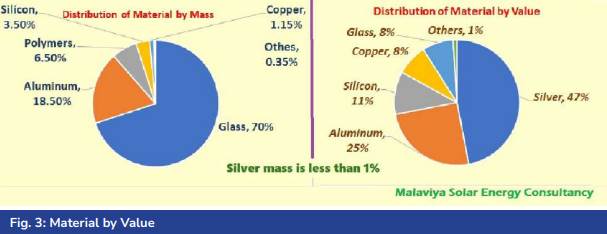

Commercial Solar Photovoltaic panel (module) is made up of various components i.e. glass, aluminium, pure silicon, copper, silver, tin, lead, phosphorous and polymer sheets. All the minerals are either critical or important dependent in India.

As the world gears up for net zero, demand for raw materials is set to soar. The energy transition presents unique challenges for metals and mining companies, which will need to innovate and rebuild their growth agenda. India has already set an ambitious target of 500 Gigawatts-peak (GWp) of Renewable Energy by the year 2030. This makes it a case of merit to adopt Circular Economy for Solar panels recycling ensuring raw materials are re-purposed for primary or secondary use.

E-waste regulation

The Ministry of Environment, Forest and Climate Change notified the E-Waste (Management) Rules, 2022 on 2nd November, 2022. Management of solar PV modules panels/ cells has been added in Chapter V of the said rule. Producers need to obtain Extended Producer Responsibility (EPR) certificates at the end of life of Solar panels by disposing safely. Solar panels have toxicity in form of antimony and lead that are hazardous besides polymers that take long to degrade. The Producers store Solar panels and cells waste generated up to the year 2034-2035 as per the guidelines laid down by the Central Pollution Control Board. Recycler of solar photo-voltaic modules or panels or cells shall be mandated for recovery of material as laid down by the Central Pollution Control Board in this regard. Higher the material recovered higher the value of EPR certificate.

Indigenous Solutions

While countries in Europe and USA have several R&D programmes to encourage developing indigenous Solar panel recycling solutions that involved no-hazardous processes and is costeconomical, India lacks such programmes if it believes in Aatmanirbhar solutions. Since India is largely important dependent for basic raw materials the metals and mining sector will be put to the test for the vast quantities of raw materials required for the energy transition. Because metals and mining are a long lead-time, highly capitalintensive sector, price fly-ups and bottlenecks will be unavoidable as demand outstrips supply and price volatility creates uncertainty around the large up-front capital investments needed for production.

Identifying Criticality

A thorough study of the raw material requirement for the anticipated targets in future and its value post recovery from recycling is crucial in order to establish economics to set-up recycling. It is also crucial government of India subsidises the cost of recycling of panels produced until November 2022 as producers (largely manufacturers) had not built in the cost of obtaining EPR certificates from recyclers.

Conclusion

India’s vast available skilled capital gives it the potential to become the global hub for Solar panel recycling. But for the purpose it will have to relax its E-waste guidelines permitting import of scrap Solar panels. This will for sure lead for more employment opportunities. A silver lining however comprehended is launching of Critical Mineral Mission in 2025 by the government to secure vital resources for green energy and technology. Added to it the carbon footprint avoided by reduced mining will benefit address Climate issues. A Producer Management Body perhaps is ideal to address the above issues. Perhaps a Ministry of Circular Economy can bolster business. – Jaideep N. Malaviya, Managing Director, Malaviya Solar Energy Consultancy