Last Updated on 28-01-2026 by Author

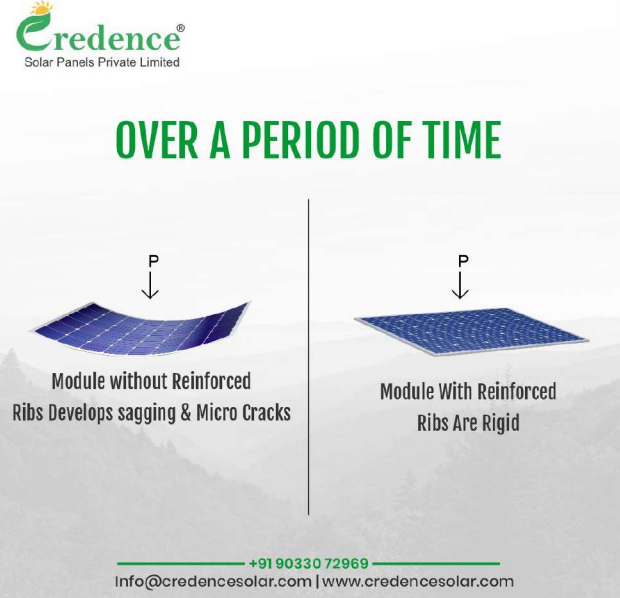

As the solar industry continues its relentless pursuit of efficiency and durability, one of the oftenoverlooked challenges in module reliability is the sagging of glass in PV modules. Glass sagging, a phenomenon where the weight of the glass combined with environmental stresses causes slight bending or deformation over time, can significantly impact the longevity and performance of solar panels.

The Impact of Glass Sagging on PV Modules

Glass is an integral structural component of a solar module, providing protection and mechanical strength to the underlying photovoltaic cells. However, as module sizes increase and ultra-highpower modules become mainstream, the risk of glass sagging also rises. Several key challenges emerge as a result of this issue:

Increased Mechanical Stress on Cells:

Sagging can lead to non-uniform pressure distribution on the solar cells, making them prone to microcracks. Over time, these microcracks can propagate, reducing the overall efficiency and accelerating performance degradation.

Higher Risk of Moisture Ingress:

Deformation can compromise the sealant integrity, making the module more vulnerable to moisture ingress, which in turn affects electrical insulation and cell performance.

Reduced Reliability Under Load Conditions:

Modules installed in high-wind or heavy-snow environments experience additional mechanical stresses. Glass sagging exacerbates these effects, increasing the likelihood of structural failures over the module’s lifespan. Understanding the significance of glass sagging in long-term performance, Credence Solar has developed an innovative solution that enhances module rigidity and durability. Their pioneering approach involves the incorporation of dual back ribs in both Monofacial and Bifacial PV modules.

Strategic Ribbing for Structural Integrity:

Credence Solar integrates two strategically placed back ribs within its high-power PV modules. This design minimizes glass sagging by providing additional mechanical support, ensuring the module retains its flat structure over time.

Enhanced Mechanical Load Tolerance:

The ribbed architecture allows modules to withstand higher static and dynamic loads, crucial for installations in regions prone to extreme weather conditions. This structural reinforcement significantly reduces the stress experienced by solar cells, extending their operational lifespan.

Superior Performance in Large-Format Modules:

With the adoption of 182mm and 210mm cell formats, larger PV modules are becoming the norm. Credence Solar’s ribbing innovation specifically addresses the mechanical challenges posed by these large-format modules, ensuring sustained efficiency and reduced power loss over their lifetime. Credence Solar’s relentless focus on technological advancements and quality-driven engineering has positioned the company at the forefront of PV module reliability. By proactively addressing glass sagging, they are not only ensuring higher efficiency but also offering enhanced durability to EPCs, developers, and end-users alike. As the solar industry marches towards higher wattage and greater efficiency, innovations like Credence Solar’s ribbed module design exemplify the importance of engineering excellence in ensuring sustainability and long-term performance. With a commitment to robust structural design, Credence Solar continues to redefine industry benchmarks, making high-performance solar technology more reliable and accessible. By expanding its facility to an impressive 2.2GW and planning a 1GW cell line, the company demonstrates its vision and commitment to a sustainable future.